In today's rapidly evolving global economy, companies face unprecedented scrutiny over the origins and environmental impact of their products. In this new world of conscious consumption, customers, governments, and investors alike are demanding transparency and accountability. This shift necessitates a profound re-evaluation of how businesses manage their supply chains. A new standard has been set—at the heart of this shift is one key principle: "Know Your Supplier" (KYS).

Just as the financial sector transformed on Know Your Customer (KYC) and Anti-Money Laundering (AML) regulations to prevent illicit activities and ensure financial integrity, businesses dealing in physical commodities now need a similar level of diligence to guarantee ethical and sustainable sourcing. Without this knowledge, companies risk serious penalties, disrupted market access, and irrevocable reputational damage.

The Limitations of Yesterday's Diligence

For decades, companies have relied on consultants and supplier questionnaires to gain supply chain visibility, but these approaches are proving woefully inadequate for today's demands—especially with regulations like the EU Deforestation Regulation (EUDR) in full effect. Wasted hours spent manually tracing a single product value chain just to come up with incomplete and immediately outdated data sets can no longer be standard practice. Surveying suppliers directly, just to receive a mere 10% response rate, was leaving companies in the dark, creating significant blind spots when it came to supply chain risks. To top it all off, regardless of value chain compliance, no method was systematically connected with local customs authorities, resulting in potential border stops without warning.

The EUDR, which mandates plot-level traceability for commodities like timber, cattle, soy, palm oil, coffee, cocoa, and rubber, encouraging deforestation-free products to reduce greenhouse gas emissions by upwards of 32 million metric tonnes annually , exemplifies this challenge perfectly. It requires companies to prove their products are deforestation-free and legally produced, demanding far more detailed origin information than ever before. Attempting to manually map hundreds of thousands of smallholder farms for a coffee company, for example, could take five years, by which time the data is already inaccurate and irrelevant.

Epoch: Automating First-Mile Visibility at Scale

This is where Epoch steps in. By transforming the landscape of supplier diligence, Epoch provides unprecedented visibility into the "first mile" of your supply chains. This is achieved through a powerful combination of AI and vast environmental data, making it possible to conduct comprehensive environmental impact monitoring at scale for thousands of suppliers simultaneously.

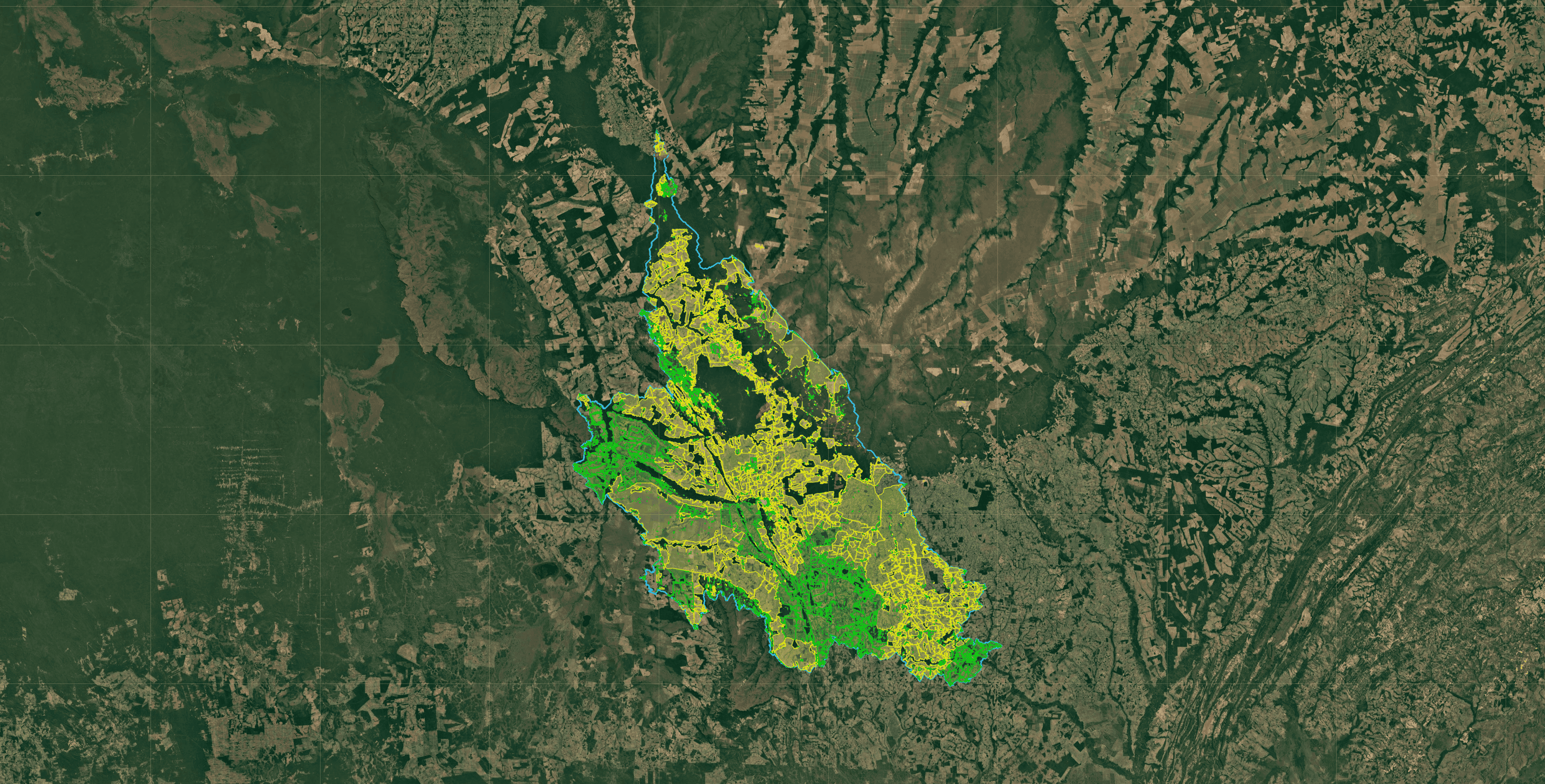

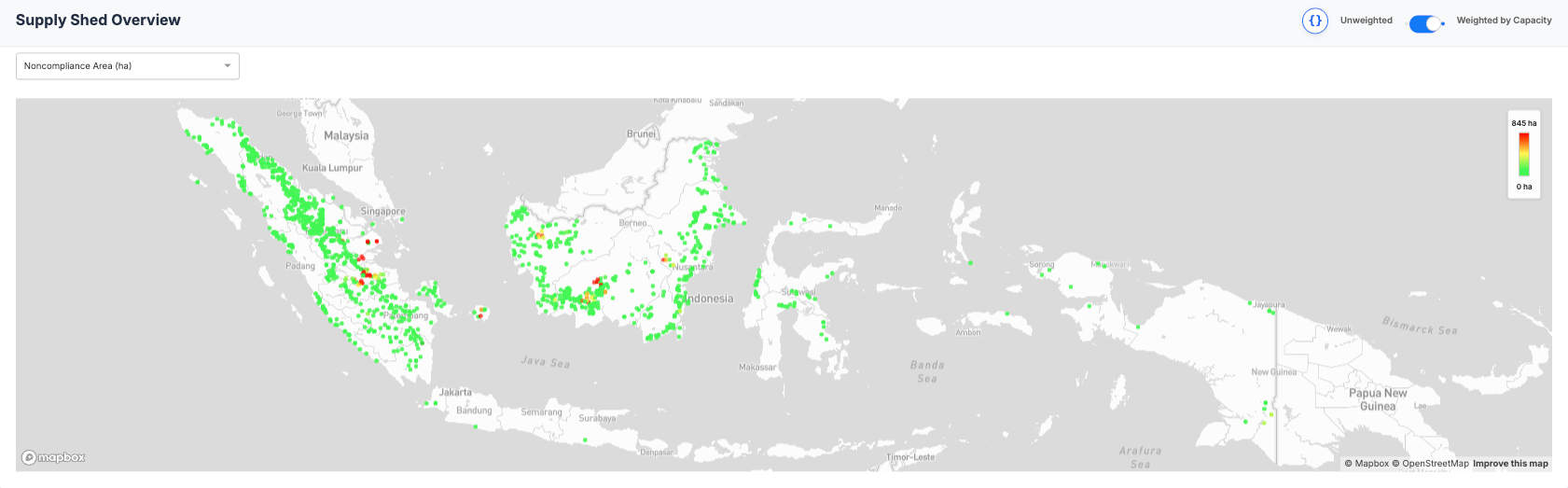

Epoch's KYS capabilities are unmatched. Our AI model begins with over a billion data points of training material from the first mile of a supply chain. Our software then automatically translates this data, identifying commodity processing facilities, their sourcing "supply sheds," and the individual plots where commodities originate. This automation allows companies to quickly focus on material sources and triage based on deforestation risk. Once target commodity plots are defined, Epoch runs multiple environmental models to generate a comprehensive footprint.

Key metrics illustrating the entire scope of possible environmental impacts include:

- Deforestation checks generate submission-ready due-diligence statements with plot level data for EUDR.

- Emissions and removals estimates for Land-Use-Change (LUC) and non-LUC emissions (from fertilizer, energy, transport) reduce dependency on supplier questionnaires.

- Water Yield model estimates uncover water holding capacity— a crucial measure of supplier resilience to floods, droughts, and extreme weather.

- Biodiversity model determines high-level, geospatially derived metrics indicating a supplier's resilience to pests and diseases.

With this level of automation, companies gain a comprehensive view of their supply chain, rather than relying solely on self-reported data or sampled audits. This gives them actionable insights, allowing businesses to identify critical suppliers with the highest risk and lowest resilience scores, and design targeted improvement programs.

Beyond Compliance: The Strategic Advantage

Adopting Epoch's automated, scalable approach to supplier diligence not only ensures compliance with regulations like EUDR but also transforms a potential regulatory burden into a strategic competitive advantage. It streamlines documentation, enables proactive risk assessment, and provides a clear, auditable trail. By embracing first-mile visibility and truly knowing their suppliers at scale, businesses can build resilient, transparent, and sustainable supply chains that meet the demands of today and the challenges of tomorrow.

Manage your supply chain risk with Epoch.

Connect with Epoch today to see how we can help you scale up supplier diligence and keep up with regulatory expectations.