From Emissions Factors to Supplier-Specific Emissions

Supply chain resilience has never been more critical. As the frequency of extreme weather events increases, the economic repercussions of climate change are becoming even clearer. Every decade, climate-related damages amount to 2.7 trillion dollars ( Munich Re )—of which 63% is sustained by the agriculture industry ( FAO ). Tropical soft commodities like coffee, cocoa, and rubber are some of the heaviest hit by climate change and most vulnerable to severe supply shocks.

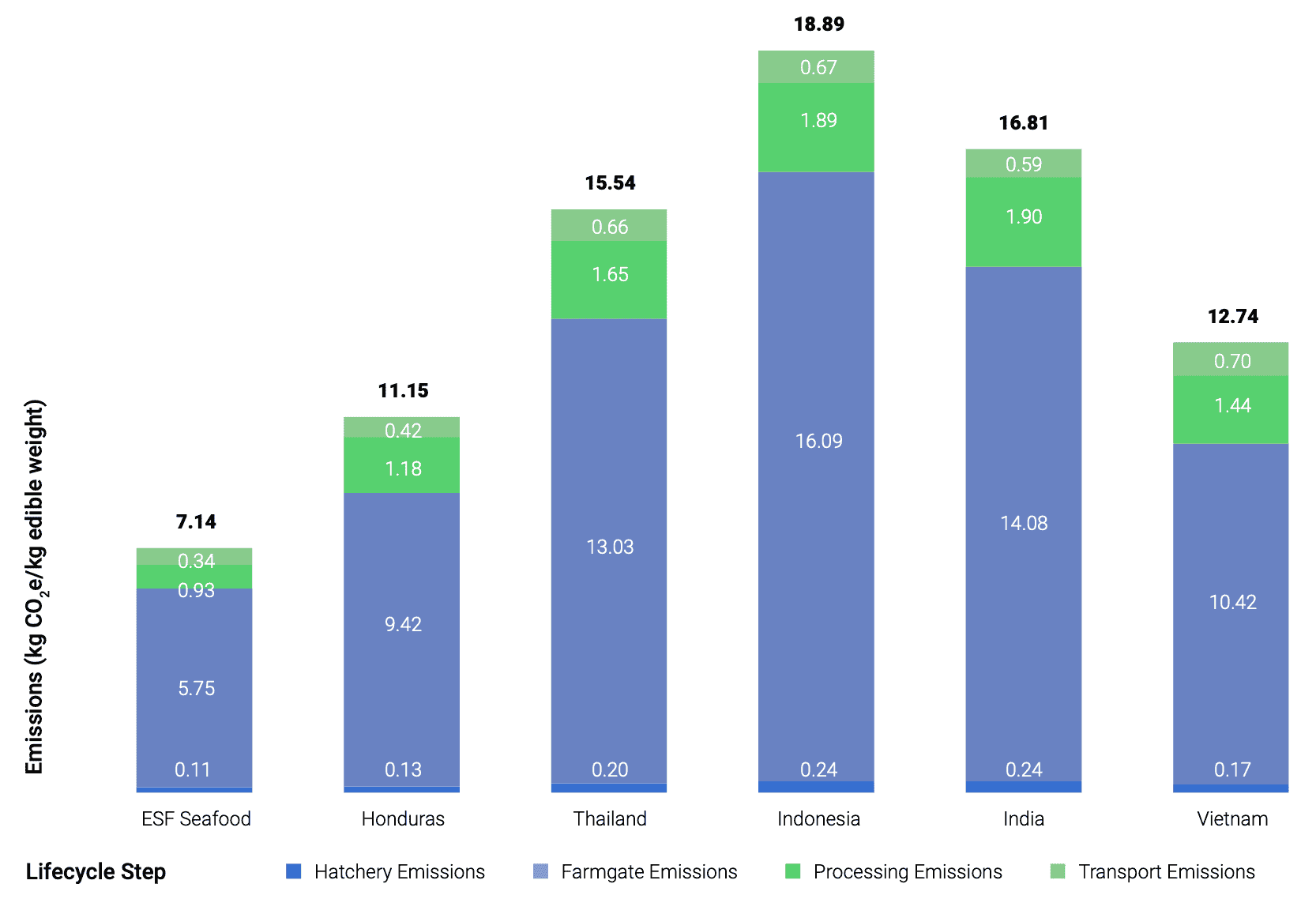

There is a clear correlation between the environmental footprint of a supply base and its resilience against extreme weather events related to climate change. Yet, measuring this footprint, especially for tropical soft commodities, has been challenging. Life Cycle Analyses (LCA) at a country level lack precision and reliability, making it difficult to accurately attribute emissions from land use change, understand specific land management practices, or account for efficiency advances at smaller scales. Traditional reliance on cascading questionnaires for supply chain assessments simply isn't feasible for enterprises with thousands of suppliers.

At Epoch, we know that transparency across your entire supply chain is essential and understand how vital mechanisms to affect change can be for fortifying irreplaceable resources. That is why transitioning away from generic emissions factors to granular, supplier-specific data is the biggest game changer you can make for the integrity and longevity of your business. Most importantly, this transition can be made at scale, analyzing thousands of suppliers without cumbersome supplier questionnaires.

By reducing supply chain risk, your products gain a competitive edge, increasing your value to business partners, prospective clients, and returning customers.

Building Resilience into Your Supply Chains

Climate action within supply chains strengthens supply base resilience and can even boost productivity for the commodities retailers and CPG companies rely on. For instance, retaining forest cover improves soil water retention and reduces flooding and erosion risks (Ellison et al., 2017), while greater biodiversity enhances disease resistance and stabilizes yields (Keesing et al., 2010). The potential gains of investing in sustainability at the scope 3 level are exponential.

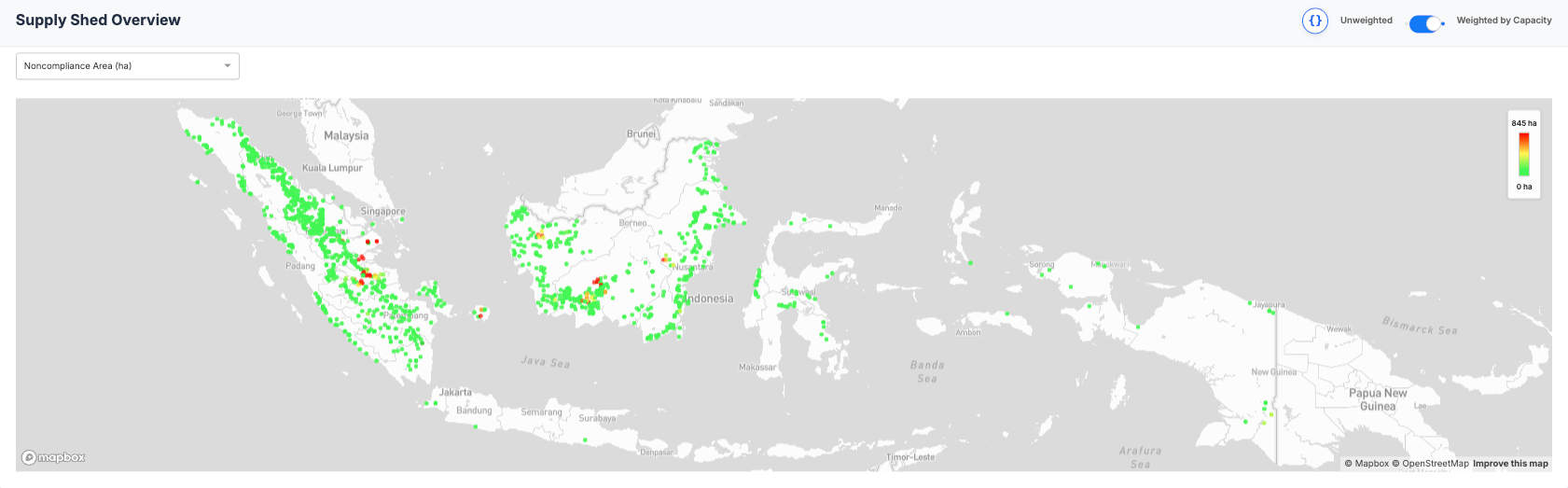

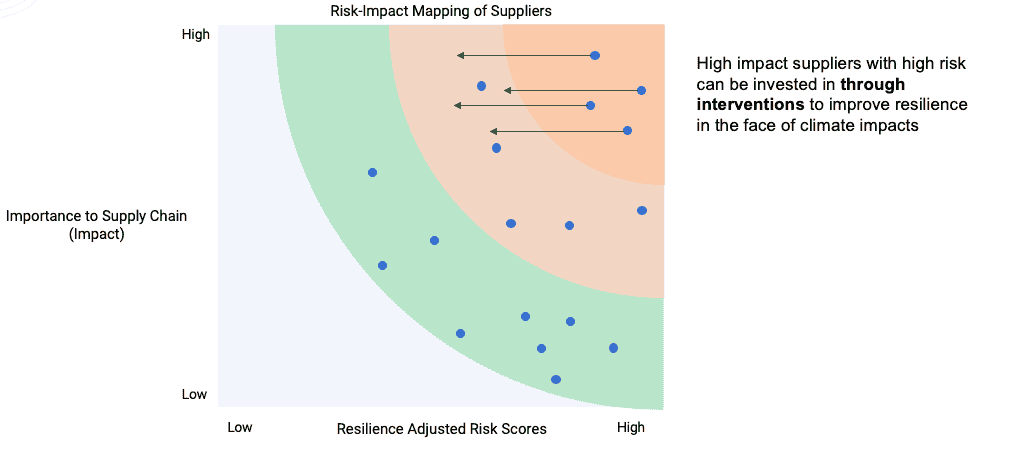

Epoch analyzes key ecological data points like forest cover, biodiversity, and water yield to identify actionable insights for prioritizing supply chain investments, indicating where interventions can build resilience in the face of climate impacts. Supplier-specific data gives companies the opportunities to better access potential risks in their supply chains— revealing which suppliers need additional support and investment, and which demonstrate resilience suitable for long-term partnerships. By leveraging your supply chain data and the best available scientific methodology, our product serves as an essential tool for mitigating supply base risk.

Stronger Compliance and More Accurate Reporting

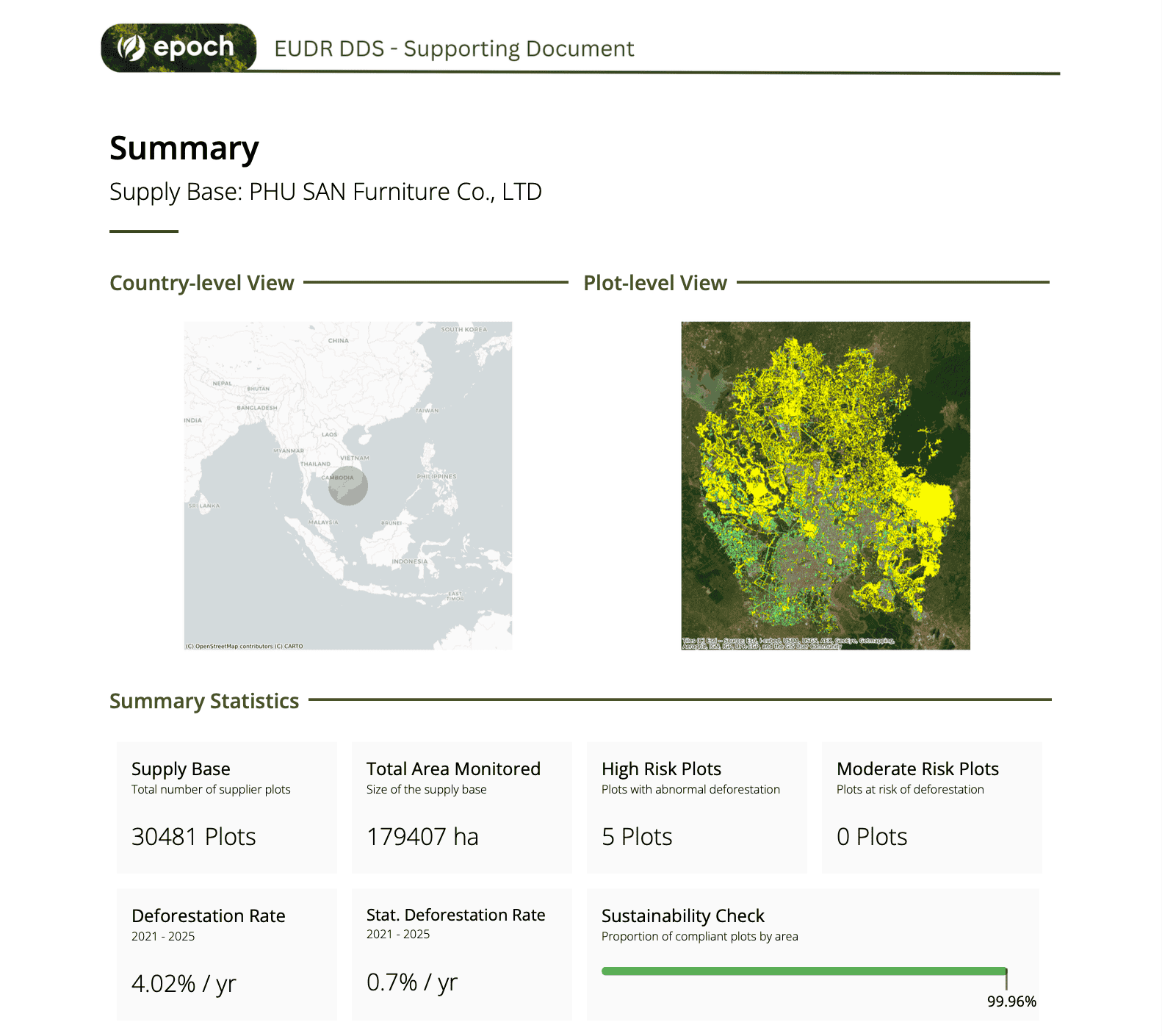

As increasing regulatory imperatives, such as the EU Deforestation Regulation (EUDR) and the Corporate Sustainability Reporting Directive (CSRD) take effect, supplier-specific data will be essential for meeting them. For EUDR compliance, companies must verify deforestation-free commodity chains. This requires supplier-specific environmental data. Having this first mile data allows for a stronger compliance posture when it comes to deforestation regulations.

Beyond the regulatory requirements, reporting on emissions and supply-chain-specific climate and nature risks are increasingly expected from capital markets, financial institutions, and insurance providers. Historically, generic emissions factors like country level LCAs often led to overestimated environmental impacts and inaccurate reporting of a company's supply chain specific risks. Supplier-specific assessments solve this problem by providing detailed data that enables accurate (frequently lower) footprint reporting and risk profiles. With your unique emissions data, businesses previously penalized for inflated emissions factors will be able to account for and benefit from their individual efforts to improve supply chain sustainability. Using this data, companies can be better informed about mitigation strategies and track performance against greenhouse gas (GHG) targets, including those related to Forest, Land, and Agriculture (FLAG) activities, covenants related to green financing, and insurance policies.

Product Differentiation

In today's competitive landscape, simply offering a quality product is no longer enough. Consumers, investors, and regulators are increasingly demanding transparency and verifiable action on climate change. In fact, European supermarkets are already starting to list environmental metrics like the carbon footprints of certain products .

Generic emissions factors are inadequate for meaningful product differentiation. By their very nature, these generalized factors make every product within a given category appear to have a similar environmental footprint, obscuring the efforts of genuinely more sustainable producers. This presents a clear opportunity for businesses to distinguish themselves from their competitors by transitioning to supplier-specific data. Moving from generic emissions factors to detailed, primary data from a single producer or supply chain empowers you to accurately calculate product specific carbon footprints to reflect the environmental impact of your operations.

This level of insight allows companies with more sustainable suppliers to leverage that data to carve a distinct position on the supermarket shelf. You can back up environmental claims with verifiable data, gaining transparency on where materials originate and how they were produced. This visibility unlocks longer-term, trusted relationships with first-mile producers and enables the design of programs and processes to drive meaningful change.

How to Drive Improvements: Decarbonization & Resilience Levers

With your unique data, the journey toward carbon neutrality and increased supply base resilience is at your fingertips. Utilizing supplier-specific reports, businesses can tackle this nuanced issue by targeting the weakest links identified in their data. Whether it be implementing systematic measures to reduce and ultimately eliminate emissions across supply chains, or developing and deploying effective mechanisms for storing and sequestering carbon from the atmosphere there are countless opportunities to build resilience and decarbonize your operations. This holistic approach, focused on reducing existing emissions and actively removing carbon from the atmosphere, not only allows for efficient and effective compliance with the GHG Land Sector and Removals Guidelines (LSRG) but also enables you to build a more sustainable business model and stand out in a competitive market.

Conclusion

Transitioning to granular, supplier-specific emissions data is fundamental for businesses aiming to navigate our changing planet. The shift from generic emissions factors to primary data provides unparalleled transparency and allows companies to build resilience against climate impacts by identifying risks and prioritizing opportunities for investment. Supplier-specific data's unique ability to ensure accurate reporting, enables you to leave behind inflated impacts, meet rapidly evolving regulatory imperatives, and demonstrate a strong compliance posture. This approach forges a clear path for product differentiation, as businesses can easily substantiate environmental claims with verifiable data and stand out to business partners, regulators, and informed consumers. Ultimately, this individualized data empowers businesses to implement tangible improvements that build resilience, bolster compliance, and ensure environmental accountability. By embracing this approach, companies are not only able to prepare for climate challenges and address supply chain variability, but also gain a competitive edge in an increasingly environmentally conscious marketplace, securing the integrity and longevity of their operations.